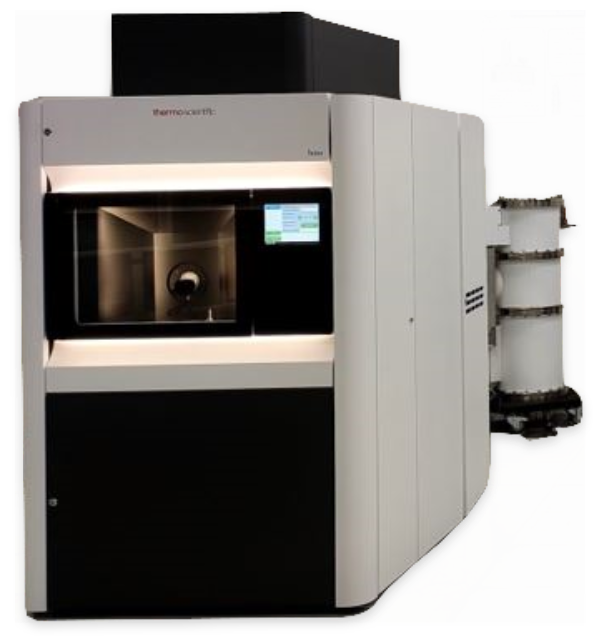

Transmission Electron Microscope (TEM)

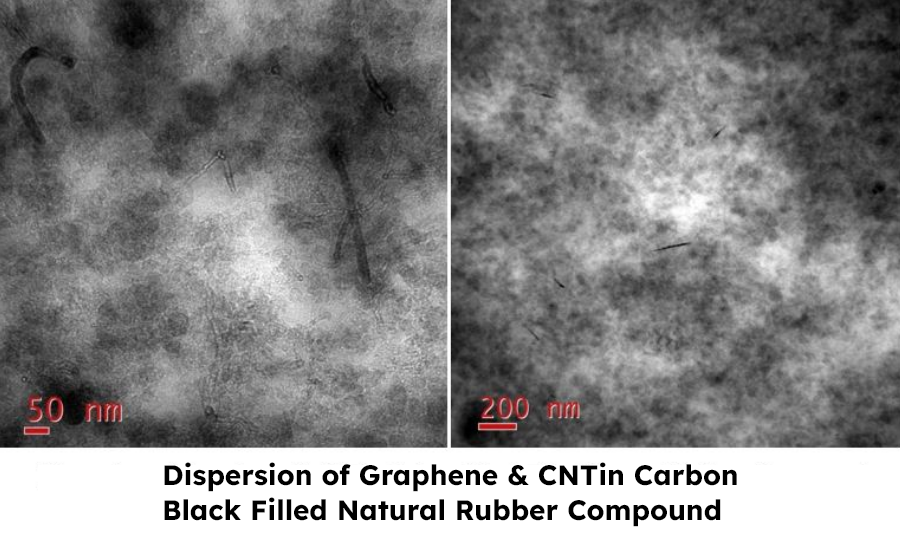

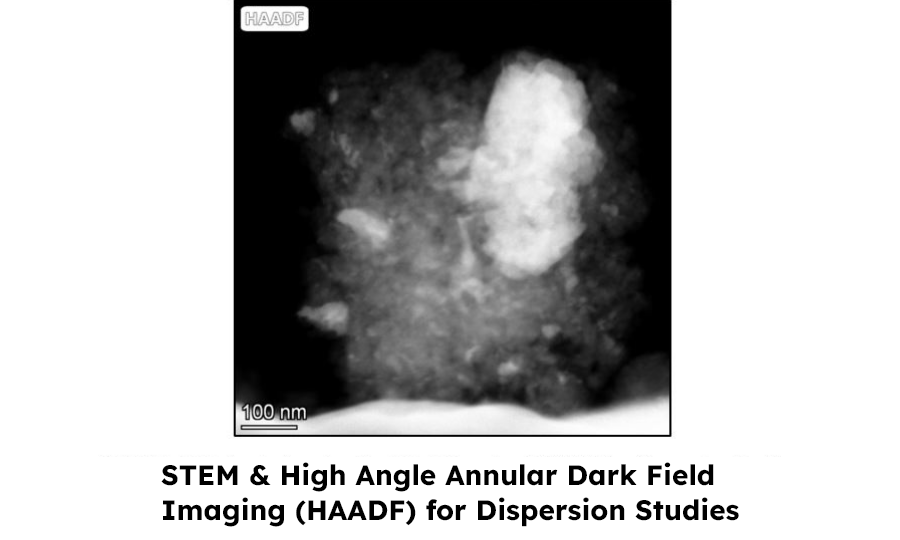

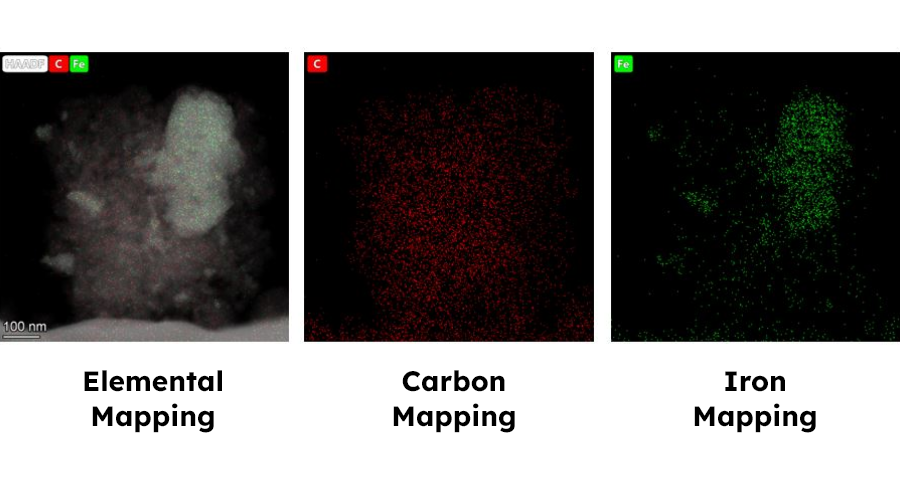

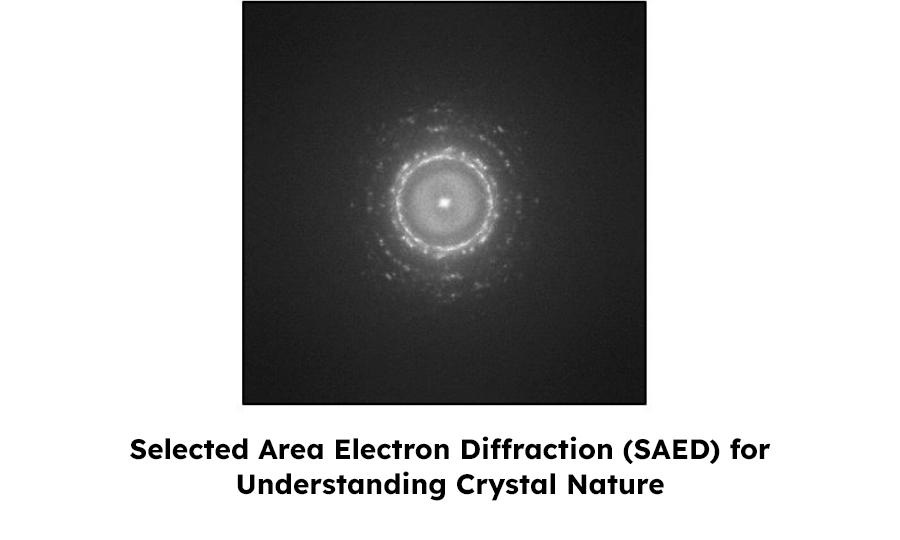

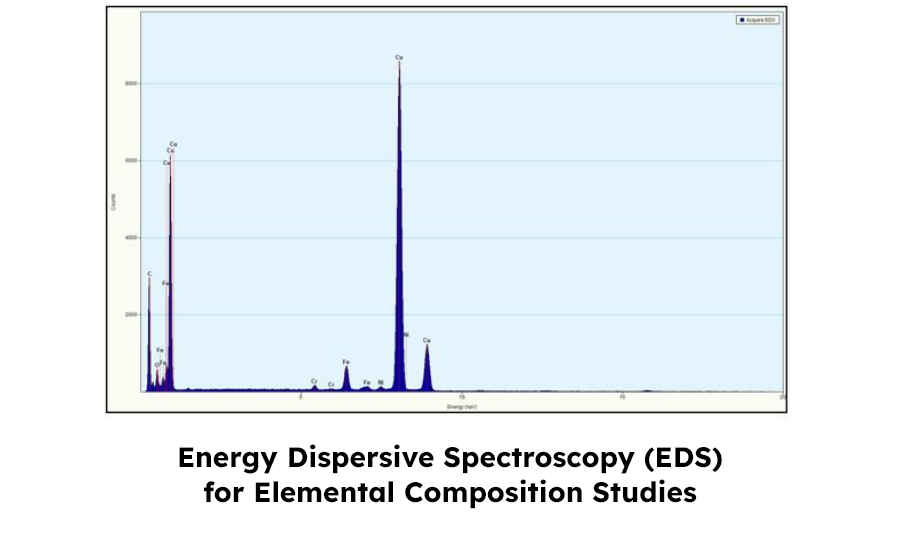

To understand the surface morphology and elemental composition of rubber compounds, HASETRI offers most precise, quantitative characterization of nanomaterials/ composites in multiple dimensions by using TEM. Information such as particle size, shape, surface morphology, topography, dispersion, quality, composition, arrangement and crystal nature can be extracted from TEM - facilitated with EDS, STEM, Elemental Mapping and Tomography.

Atomic arrangement and elemental composition of any compound is an essential criterion to understand / to obtain desired properties of it. Various physical and chemical properties such as Durability, Hardness, Rebound resilience, impermeability and adhesiveness etc., are resultant of material dispersion and composition. Hence, TEM will provide both Qualitative and Quantitative understanding of material behaviour and product performance.

It is possible to perform material studies through various modes available in TEM:

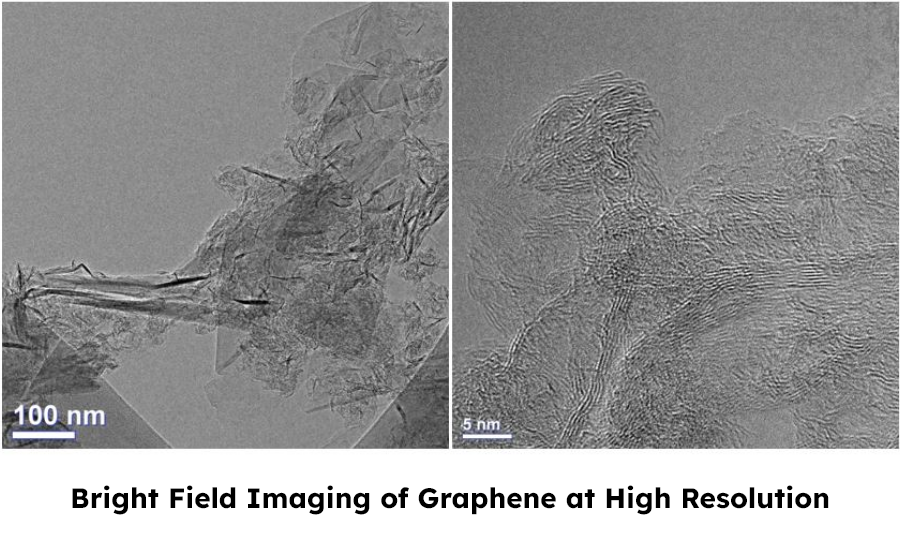

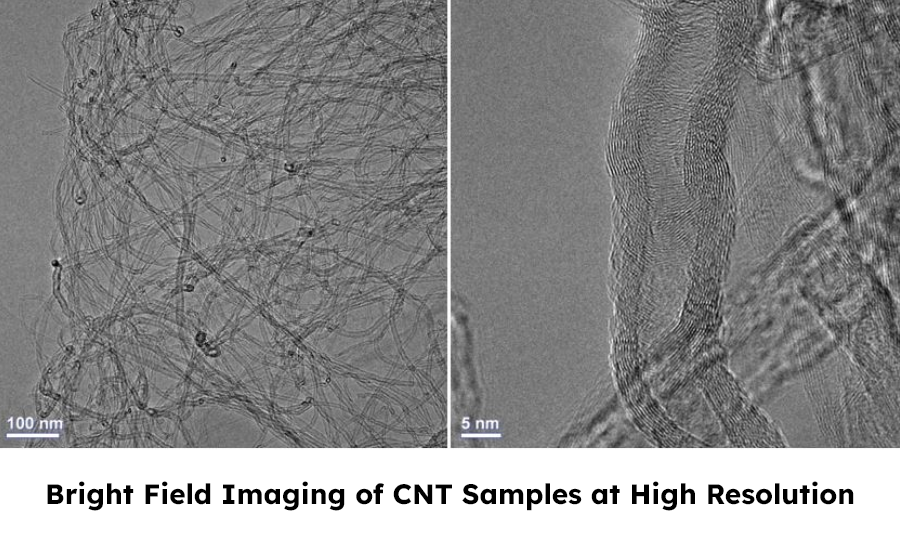

- Bright Field Imaging

- Dark Field Imaging

- High Angle Annular Dark Field imaging

- Individual element Mapping with Auto Drift

- Region specific Mapping

- Point Mapping

- Selected Area Electron Diffraction(SAED)

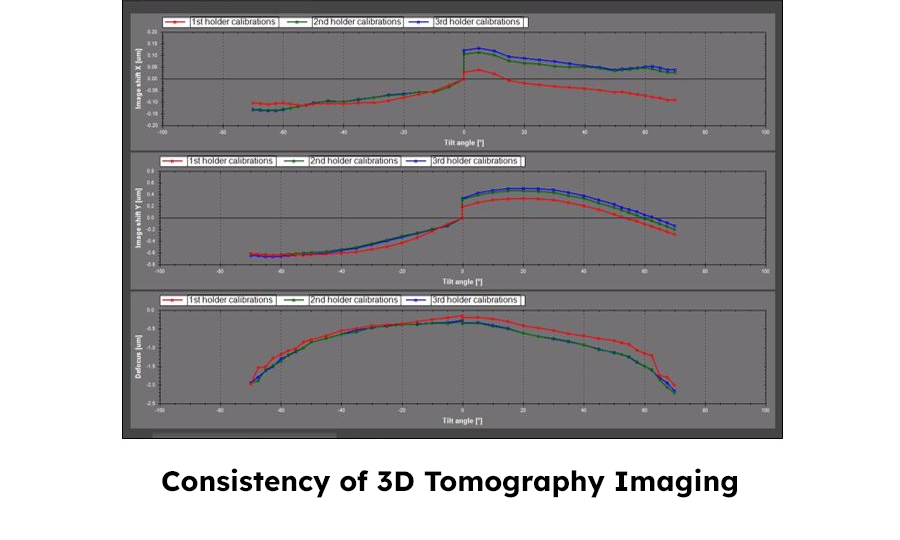

- 2D and 3D Tomography

- Scanning Transmission Electron Microscopy

- Energy Dispersive Spectroscopy (EDS)

TEM Applications

- A Transmission Electron Microscope is ideal for a number of different fields such as life sciences,

nanotechnology, medical, biological and material research, forensic analysis, gemology and

metallurgy as well as industry and education.

- TEM provides topographical, morphological, compositional and crystalline information.

- The images allow researchers to view samples on a molecular level, making it possible to analyse

structure and texture. This information is useful in the study of crystals and metals and also has

industrial applications.

- TEM can be used in semiconductor analysis and production & manufacturing of computer and silicon

chips.

- Technology companies use TEMs to identify flaws, fractures and damages to micro-sized objects; this

data can help fix problems and/or help to make a more durable, efficient product.