Failure Analysis

- Home

- /

- Working Domain

- /

- Sponsored Research and Technology...

- /

- Failure Analysis

Failure Analysis

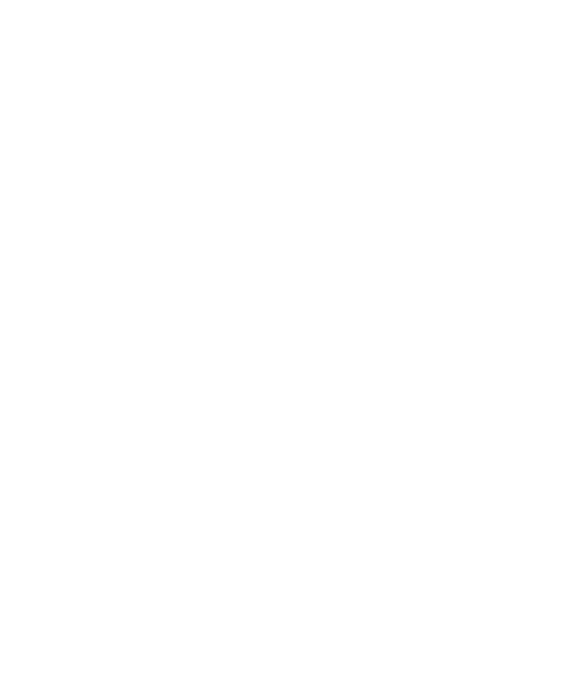

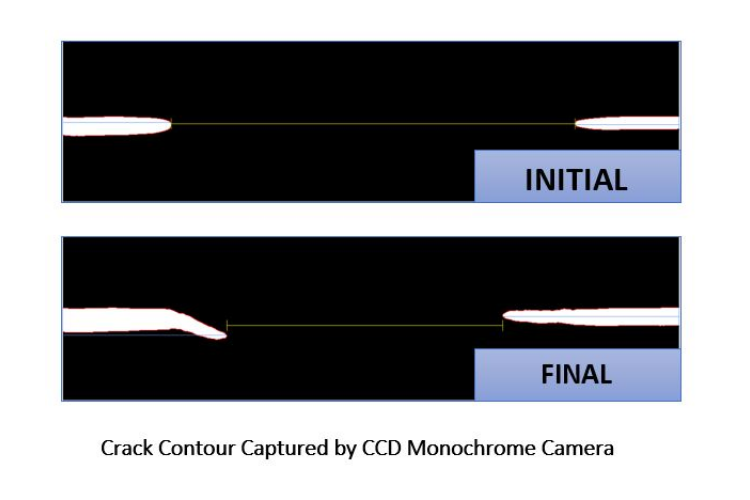

Fatigue Crack Growth (FCG) Analysis:

To understand the durability of rubber compound, HASETRI offers prediction of Crack nucleation and crack growth rate at different operating condition.

Fatigue crack growth (FCG) behaviour of elastomer compounds is an essential criterion to understand the cause of failure. As most of elastomer product undergoes millions of fatigue cycles during their service life, one micro-crack can leads to an ultimate failure if FCG characteristic of that compound is not sufficient enough to restrict the propagation. There are various factors which influence the FCG characteristics of rubber vulcanizates viz. temperature, strain rate, type of elastomer and filler etc.

It is possible to measure FCG at different environmental conditions:

- High Temperature (Max 150oC)

- Low Temperature (Min -50oC)

- Inert (Nitrogen), Oxygen and Ozone atmosphere

- Different loading conditions:

- Variable Strain

- Waveforms (Sine, Pulse etc.)

- Variable Frequency

- Non-relaxing load (R-Ratio)

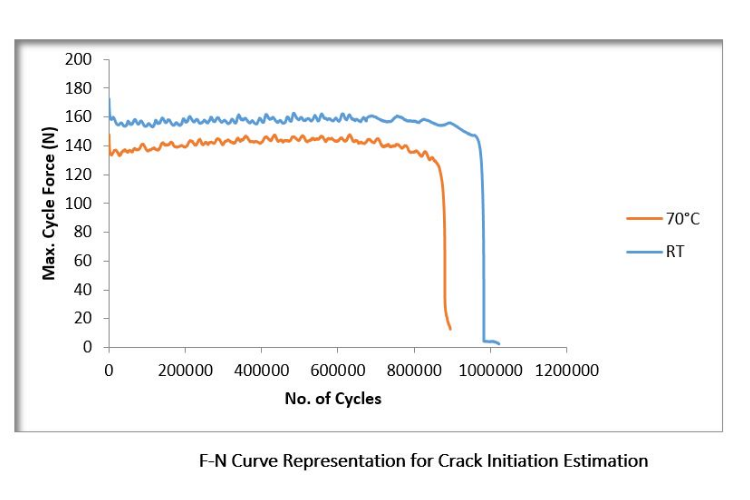

Microscopic Analysis:

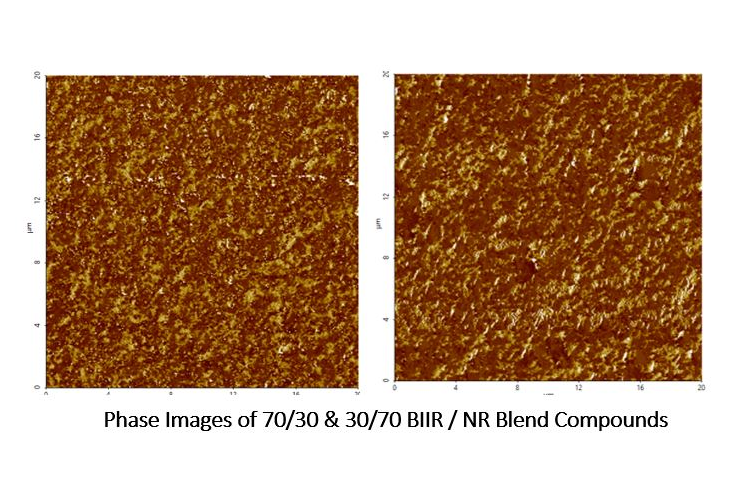

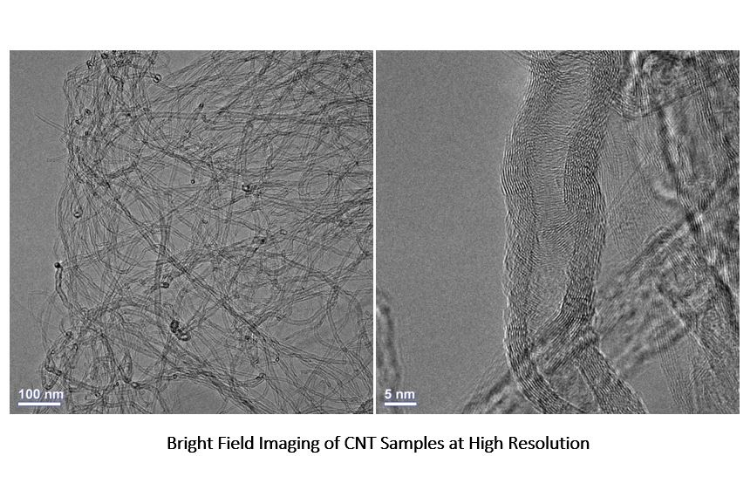

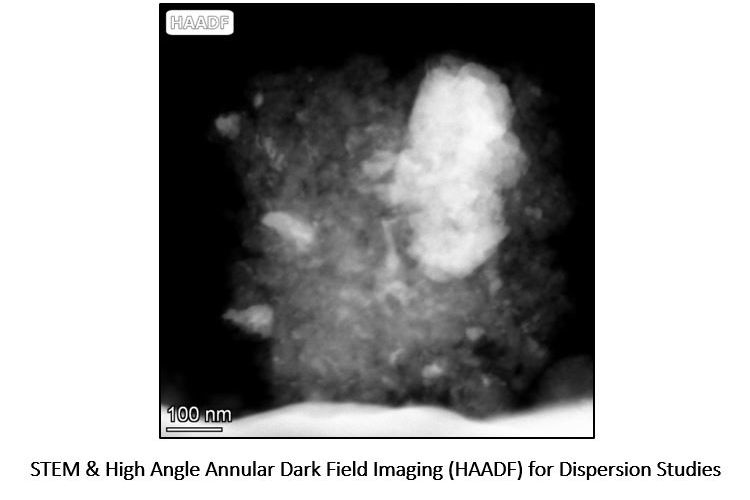

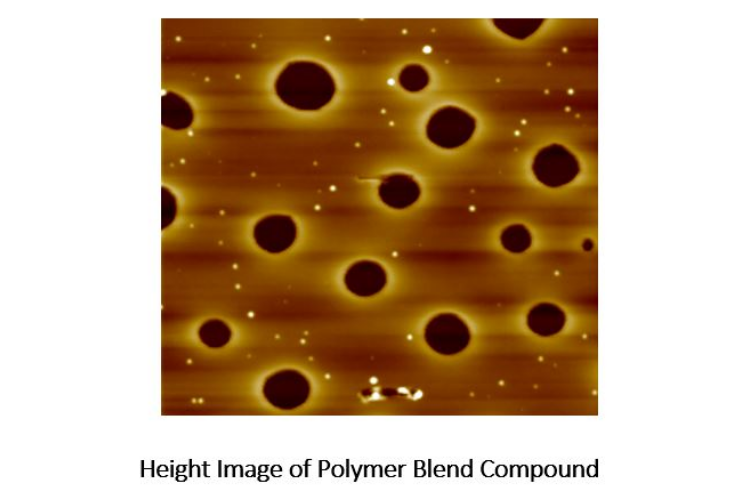

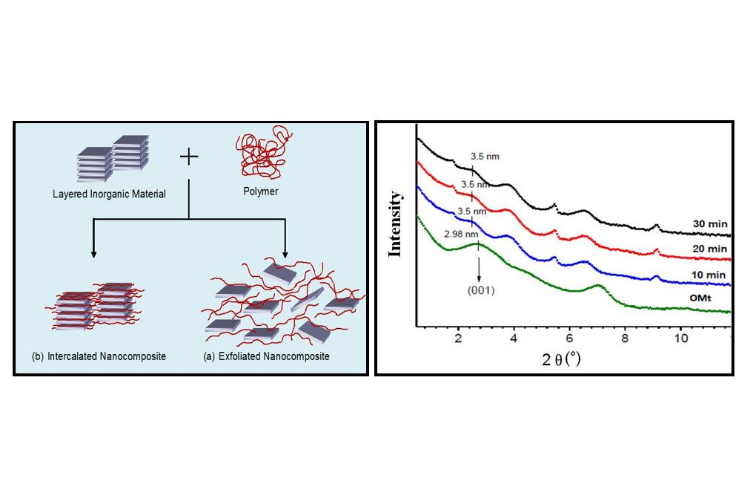

To understand the topography and morphological characteristics of the compound, HASETRI offers Optical and Scanning Electron Microscopic (SEM) analysis for different Samples including sectioning of the thin specimen (100 nm) by Ultramicrotomy.

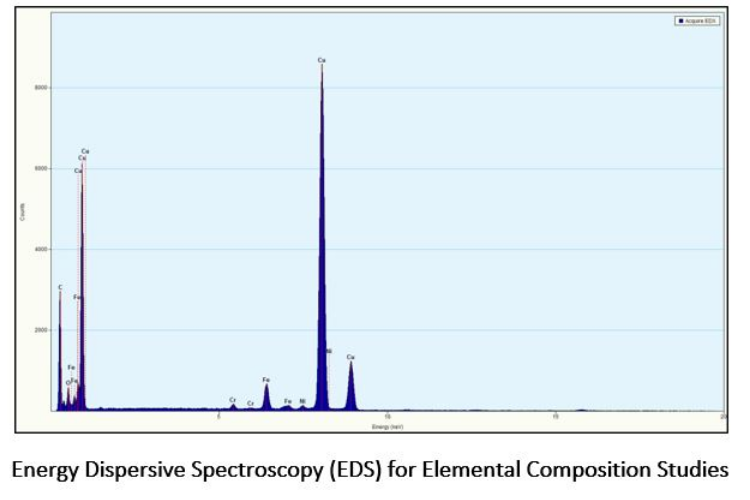

Microscopic analysis of any substance is important to understand the several phenomenons such as: dispersion behaviour of fillers, topography of fracture surface, root cause analysis of failure etc. To understand the chemical composition of any material, we characterise them through Energy Dispersive Spectra (EDS) also where mapping of individual element (Such as Zn, Sulphur and Silica etc.) can be done via point or line scan mode.

IHASETRI can offer to analyse materials with different modes:

- Optical Microscopic Images

- Secondary Electron Images

- Back Scattered Electron Image

- Individual element Mapping

- Line Scan Mapping

- Point Mapping

Highlights

HASETRI featured in Indian/International Rubber Journal

An enlightening interview with Dr. R. Mukhopadhyay, Director & CE, HASETRI, speaks of the current situation of the Indian tire and rubber industry and how they are coping with the pandemic.

HASETRI successfully enhanced the scope of NABL accreditation

September 2021: HASETRI has successfully enhanced the scope of NABL accreditation in Wet Grip and Coast by Noise testing for Cl & C2 category tyres as per ECE R117 and proposed AIS 142.

PHD Annual Awards for Excellence Announced

HASETRI imparted training to candidates under the STAR scheme of NSDC,GOI in rubber sector(under Rubber SDC)for the job roles of mill & Tyre Building Operator-commercial vehicles. The Institute has been approved as the first training provider for rubber sector by RSDC under NSDC,GOI